Industrial Washing Machines in Aerospace Assembly Plants: Cleaning Assembled Aircraft

Introduction

Aerospace assembly plants are at the epicenter of cutting-edge technology and engineering. These plants are responsible for the meticulous assembly of aircraft, ensuring that every component is flawlessly integrated to ensure the highest safety standards. However, the assembly process often leaves behind various contaminants such as oils, grease, dust, and residues. To address this issue, industrial washing machines have emerged as a crucial tool in the aerospace industry. These powerful machines not only clean assembled aircraft but also play a pivotal role in maintaining the regulatory standards and performance of the aircraft. This article delves into the significance of industrial washing machines in aerospace assembly plants and their invaluable impact on the cleanliness and efficiency of aircraft.

Improved Cleaning Efficiency and Precision

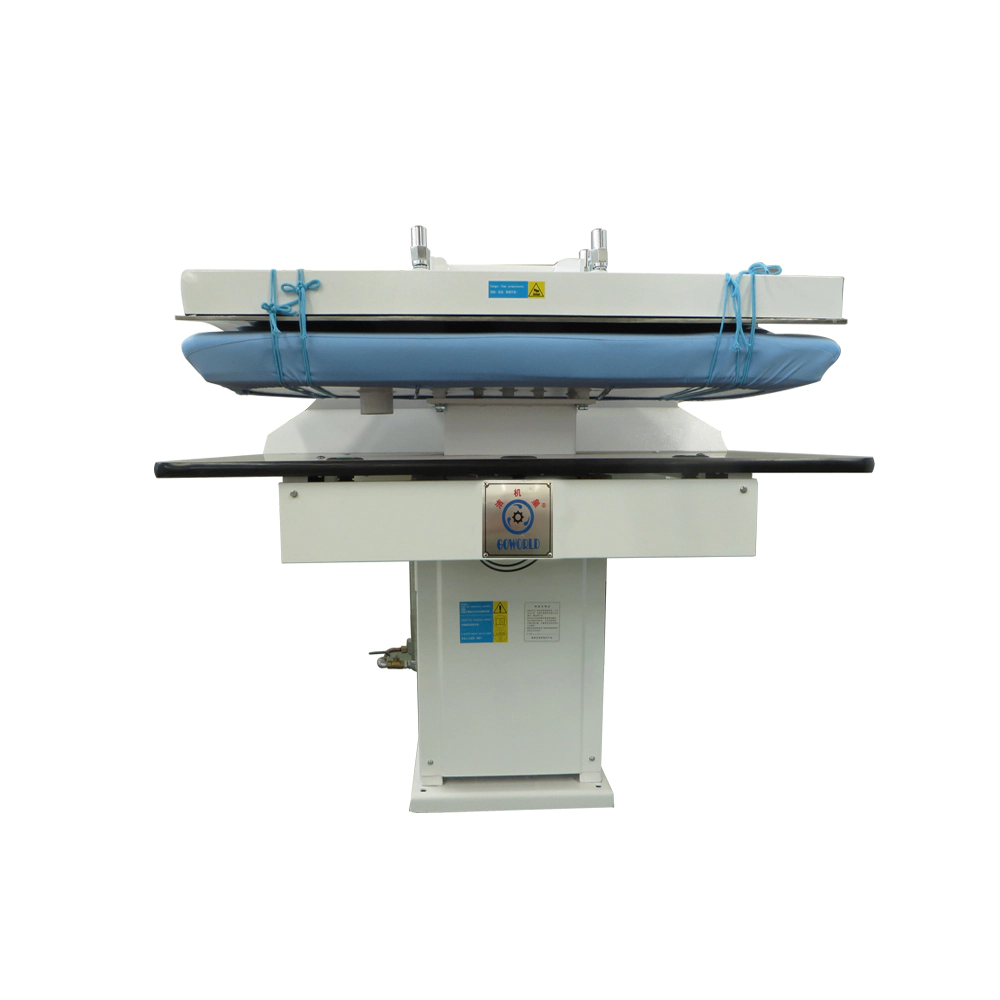

Industrial washing machines bring about a revolution in the cleaning process of assembled aircraft in aerospace assembly plants. Traditional cleaning methods were often labor-intensive, time-consuming, and less effective. However, with the advent of industrial washing machines, the cleaning process has become highly efficient and precise. These machines are equipped with advanced technology and intelligent features that ensure thorough and consistent cleaning of every surface of the aircraft.

Industrial washing machines utilize high-pressure water jets, detergents, and specialized cleaning agents to remove contaminants from the aircraft's exterior and interior surfaces. The high-pressure water jets effectively dislodge dirt, grime, and other stubborn deposits, while the detergents and cleaning agents help break down and remove oils, grease, and chemical residues. Additionally, these machines offer customizable cleaning cycles and settings to cater to different aircraft types, ensuring precise cleaning tailored to each aircraft's specifications.

Ensuring Regulatory Compliance and Safety Standards

Industrial washing machines play a pivotal role in ensuring regulatory compliance and safety standards in aerospace assembly plants. The aerospace industry is strictly governed by various regulatory bodies that impose stringent cleanliness requirements for aircraft. Failure to meet these standards can result in severe penalties and compromise the safety and functionality of the aircraft.

By utilizing industrial washing machines, aerospace assembly plants can achieve the required cleanliness benchmarks set by regulatory agencies. These machines offer comprehensive cleaning solutions that eliminate contaminants with precision, leaving no room for non-compliance. The consistent application of appropriate cleaning agents and procedures ensures that all surfaces are thoroughly cleaned, minimizing the risk of potential hazards such as corrosion, electrical malfunction, or compromised structural integrity.

Extended Lifespan of Aircraft Components

One of the significant advantages of industrial washing machines in aerospace assembly plants is their contribution to extending the lifespan of aircraft components. Aircraft often operate under harsh environmental conditions, subjecting the components to wear, corrosion, and degradation over time. Effective maintenance and cleaning practices are vital to ensure the durability and longevity of these components.

Industrial washing machines enable aerospace assembly plants to conduct regular and thorough cleaning of aircraft components, thereby preventing the accumulation of contaminants that could lead to premature failure or deterioration. By removing oils, debris, and other impurities, these machines help preserve the integrity of critical components such as engines, hydraulic systems, and avionics. This, in turn, improves the overall reliability and performance of the aircraft, reducing the need for frequent maintenance and component replacements.

Enhanced Productivity and Cost Efficiency

The integration of industrial washing machines in aerospace assembly plants brings about a significant boost in productivity and cost efficiency. Traditional cleaning methods relied heavily on manual labor and often required extensive dismantling of aircraft components, leading to increased downtime and reduced efficiency. However, industrial washing machines streamline the cleaning process, allowing for faster turnaround times and improved productivity.

These machines are adept at cleaning assembled aircraft without the need for extensive dismantling, as they are designed to access hard-to-reach areas and eliminate contaminants thoroughly. The automated cleaning cycles and settings significantly reduce the time required for cleaning, enabling assembly plants to maximize their operational efficiency and minimize aircraft downtime. Moreover, the cost savings achieved through reduced labor requirements and enhanced component lifespan contribute to improved cost efficiency in the long run.

Conclusion

Industrial washing machines have become an indispensable tool in aerospace assembly plants, revolutionizing the cleaning process of assembled aircraft. The precision, efficiency, and regulatory compliance offered by these machines ensure that assembled aircraft meet the highest cleanliness standards, enhancing safety and performance. With their ability to extend the lifespan of aircraft components and improve productivity, industrial washing machines have emerged as a key investment for aerospace assembly plants, delivering long-term cost benefits. As the aerospace industry continues to propel forward, the effective integration of industrial washing machines will remain vital in ensuring the cleanliness, regulatory compliance, and efficiency of assembled aircraft.