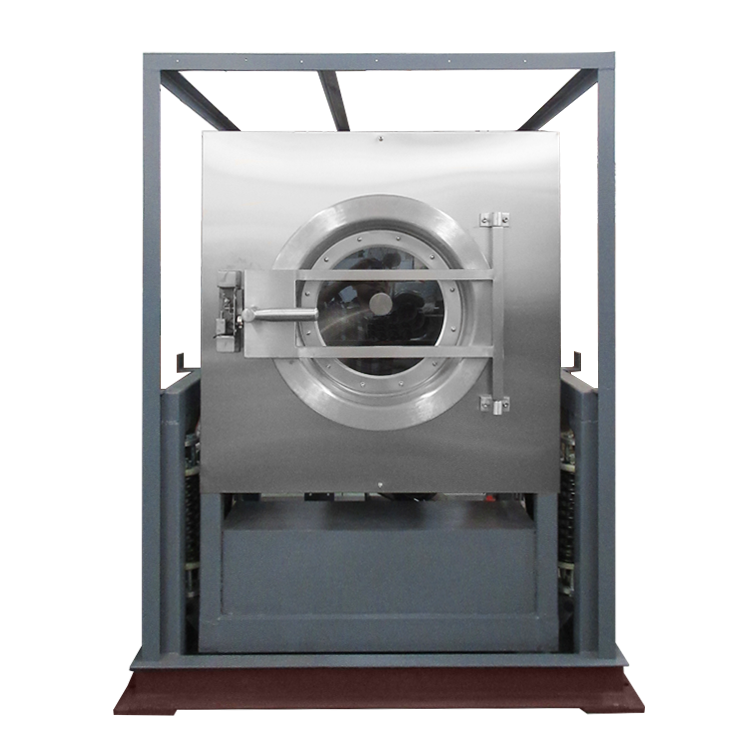

Industrial Washing Machines in Research Facilities: Cleaning Lab Equipment and Glassware

Introduction

Cleaning lab equipment and glassware is a crucial aspect of maintaining a sterile and efficient research facility. Industrial washing machines designed specifically for research facilities have become indispensable tools in laboratories worldwide. These advanced machines offer a quick and effective way to clean a wide range of delicate laboratory equipment, ensuring that experiments are conducted with accuracy and reliability. In this article, we will delve into the benefits and features of industrial washing machines used in research facilities, exploring their significance in maintaining a clean and organized laboratory environment.

The Importance of Clean Lab Equipment

Maintaining clean lab equipment and glassware is essential for several reasons. First and foremost, ensuring cleanliness prevents cross-contamination between samples, thus minimizing the risk of producing inaccurate experimental results. Dust, residues, or contaminants left behind from previous experiments can compromise the integrity of new tests, leading to invalid or misleading conclusions. Moreover, maintaining hygienic laboratory equipment contributes to the safety of researchers by reducing exposure to potentially hazardous substances.

Cleanliness also plays a pivotal role in extending the lifespan of lab equipment. Glassware, for instance, can become etched or scratched over time due to repeated exposure to harsh chemicals or improper cleaning methods. This can alter the surface properties of the glass and affect subsequent experiments. By utilizing specialized industrial washing machines, research facilities can minimize the wear and tear on their equipment, ultimately reducing replacement costs.

Features of Industrial Washing Machines in Research Facilities

Industrial washing machines tailored for research facilities offer a myriad of features that cater to the unique needs of laboratories. These machines are designed to handle delicate glassware and lab equipment efficiently, ensuring optimal cleaning results without compromising their integrity. Let's explore some of the key features of these machines.

1. Advanced Cleaning Techniques

Industrial washing machines employ advanced cleaning techniques to achieve thorough and effective cleaning. These techniques include high-pressure water jets, ultrasonic cleaning, and specialized detergents. High-pressure water jets can dislodge stubborn residues, while ultrasonic cleaning utilizes sound waves to generate tiny bubbles that gently remove contaminants from hard-to-reach areas. The use of specialized detergents ensures a comprehensive cleansing process, removing even the most stubborn stains and residues.

2. Versatile Washing Programs

Research facilities deal with a wide variety of lab equipment and glassware, each requiring a tailored cleaning approach. Industrial washing machines offer versatile washing programs that can be customized for specific cleaning requirements. From delicate glass tubes to metal instruments, these machines provide a range of washing programs to ensure thorough and efficient cleaning without causing damage. This versatility allows laboratories to streamline their cleaning processes and save valuable time.

3. Adjustable Water Temperature and Pressure

Different lab equipment and glassware may require specific water temperature and pressure settings to ensure optimal cleaning results. Industrial washing machines allow users to adjust these variables according to their specific needs. For temperature-sensitive glassware, lower water temperatures can be selected, whereas higher pressure can be employed to tackle more stubborn contaminants. This flexibility gives researchers the confidence that their equipment will be thoroughly cleaned without compromising its integrity.

4. Drying Capabilities

After the cleaning process, it is vital to ensure that lab equipment and glassware are completely dry before their subsequent use. Moisture can interfere with experiments or compromise the accuracy of measurements. Industrial washing machines equipped with drying capabilities use hot air to remove all traces of moisture from the equipment, ensuring that it is immediately ready for use. This feature eliminates the need for time-consuming manual drying methods, further enhancing the efficiency of laboratory operations.

5. User-friendly Interface and Safety Measures

Industrial washing machines designed for research facilities prioritize user-friendliness and safety. These machines feature intuitive interfaces that allow researchers to easily select the appropriate washing programs and adjust settings. Additionally, safety measures such as automatic door locks, emergency stop buttons, and leak detection systems ensure the well-being of laboratory personnel. These safety features minimize the risks associated with handling hazardous substances and prevent accidents in the laboratory environment.

Conclusion

Industrial washing machines have revolutionized the cleaning process of lab equipment and glassware in research facilities. With their advanced cleaning techniques, versatile washing programs, adjustable water temperature and pressure, drying capabilities, and user-friendly interfaces, these machines have become indispensable assets in laboratories worldwide.

Maintaining clean lab equipment is vital for accurate experimental results, preventing cross-contamination, and prolonging the lifespan of instruments. By investing in industrial washing machines, research facilities can optimize their cleaning processes, streamline their operations, and ensure the safety of their personnel. The use of these machines is a testament to the commitment of research facilities towards maintaining a sterile, efficient, and organized laboratory environment.